The natural gas transmission networks

The Networks division has four key missions:

1 - Operation and maintenance

2 - Transport and delivery

3 - The monitoring and supervision of the natural gas transmission networks - Safety on gas sites

4 - Infrastructure Development

1 - OPERATION AND MAINTENANCE

Operating and maintaining its transport infrastructure to ensure high availability

Gaznat's operations and maintenance staff carry out maintenance work on the infrastructure. The work is diverse and varied; in particular, the following activities can be mentioned:

1) Mechanical maintenance in the stations (delivery stations)

The various pressure regulation, filtering and preheating devices require regular maintenance which is carried out by our mechanics. Our teams also accompany the federal inspectors for an annual safety inspection of all our installations.

2) Follow-up of the cathodic protection (anti-corrosion protection)

The cathodic protection specialists permanently check that the buried gas pipelines are well protected by an adequate electric current on the whole Gaznat network. They regularly carry out measurements, issue reports and maintain the cathodic protection equipment which ensures the protection against corrosion.

Field measurements by our cathodic protection specialists

Field measurements by our cathodic protection specialists

3) Maintenance and control of the electrotechnical installations

The team of electricians ensures the proper functioning of all the equipment used to remotely control the network stations. Gaznat's staff carries out an annual mandatory regulatory inspection (OIBT) of all installations. Checks and calibration of energy metering instruments are also carried out by metrology specialists.

4) Control of the route

In accordance with the Ordinance on Safety Requirements for Pipeline Installations, the route, ancillary installations, protective structures and markers are checked every two weeks.

Any damage to the installation can only be detected by periodic inspections, which are carried out according to pre-established programmes specifying the type of inspection to be carried out and their frequency. The means used are land inspections (by car or on foot) and air inspections (by helicopter or drone). The main objective of the periodic inspections is to check the pipeline route for any actions undertaken by third parties who do not have a work permit, or for damage due to natural forces. The safety of the network is guaranteed by the close collaboration between Gaznat, its agents, the municipalities and all the landowners and tenants affected by the gas installations.

Helicopter air traffic control

Helicopter air traffic control

5) Safety of gas pipelines

In addition to the external insulating coating and in order to guarantee the integrity of the steel pipelines against corrosion, they are under active cathodic protection.

In addition, to ensure the integrity of the pipelines, an internal inspection is carried out every 10 years using instrumented pistons in order to detect thickness defects and dents in the pipeline.

Smart pig used to monitor the gas pipelines for damage

Smart pig used to monitor the gas pipelines for damage

In order to detect leaks (gas being an odorless molecule), an odorant is added to it, thus allowing to detect the presence of gas well before the danger threshold is reached. In case of detection of a gas odor, the operator of the concerned facilities should be called immediately.

The presence of the gas pipeline is identified by beacons on which a call number and an identification number are written.

Marker post identifying the route of a gas pipeline

Marker post identifying the route of a gas pipeline

6) The monitoring of third-party work

In order to protect people and property, the Swiss Federal Pipelines Act and its implementing ordinances require prior authorization from the competent supervisory authority for the execution of third-party projects that could endanger a gas pipeline.

Third-party construction projects are all construction, agricultural or forestry activities, as defined in Art. 28 of the Swiss Federal Pipelines Act, carried out in the safety zone of gas pipelines or related high-pressure installations.

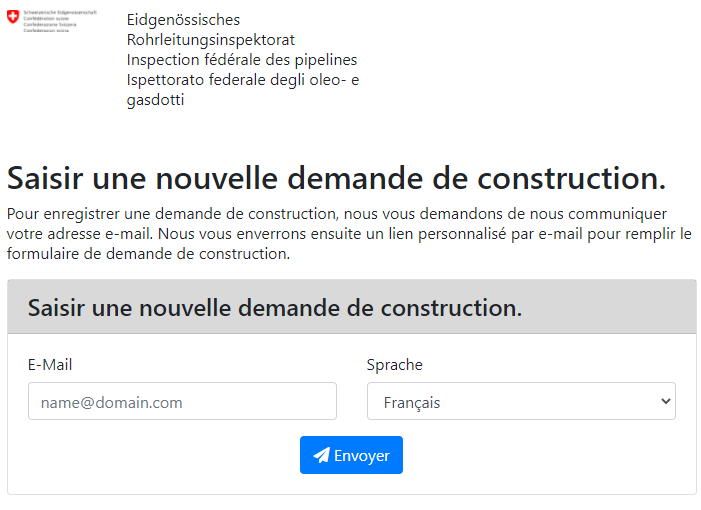

The authorization procedure follows the process described on the page below (click on the image to access the form):

2 - TRANSPORTATION AND ROUTING

To transport and deliver gas through its networks in accordance with the needs of its clients in terms of energy and time.

3 - THE MONITORING AND SUPERVISION OF THE NATURAL GAS TRANSMISSION NETWORKS

To monitor and operate the networks in order to deliver gas in accordance with clients' needs while ensuring the safety of goods and people.

4 - INFRASTRUCTURE DEVELOPMENT

To develop its infrastructure to meet the needs of its clients and reduce its carbon footprint.

The development of the networks is carried out by the engineering department, which studies the development, planning, construction and commissioning of all new installations related to the gas network. The network department performs a function similar to that of an engineering office, with specific experience and know-how in the field of high-pressure natural gas transport.

In order to carry out its various missions, the network department is composed of a team representing various fields: mechanical engineering, electricity, industrial computing, telecommunication and geomatics, mechanics, electrical engineering, specialized mechanical and electrical drawing, software development and dispatching operators.

The engineering department deals in particular with :

- the construction of new gas pipelines

- the construction of delivery stations;

- the work necessary for the operation of the networks.

The employees of the networks department work in close collaboration in order to fulfil the missions entrusted to them while respecting the safety of people and property and ensuring a high level of security of supply for our customers.

Aerial view of gas pipeline laying at Chavannes-de-Bogis

Aerial view of gas pipeline laying at Chavannes-de-Bogis