Consideration of the site's energy autonomy and Research & Development: a holistic approach

The dispatching center, the nerve center for monitoring gas movements in western Switzerland's high-pressure transmission networks, has been the subject of a comprehensive review since 2018. As a safety measure due to the site's strategic function, and in order to implement its vision of CO2-neutral gas by 2050, Gaznat carried out a study to determine the site's energy needs and its potential in terms of renewable energies.

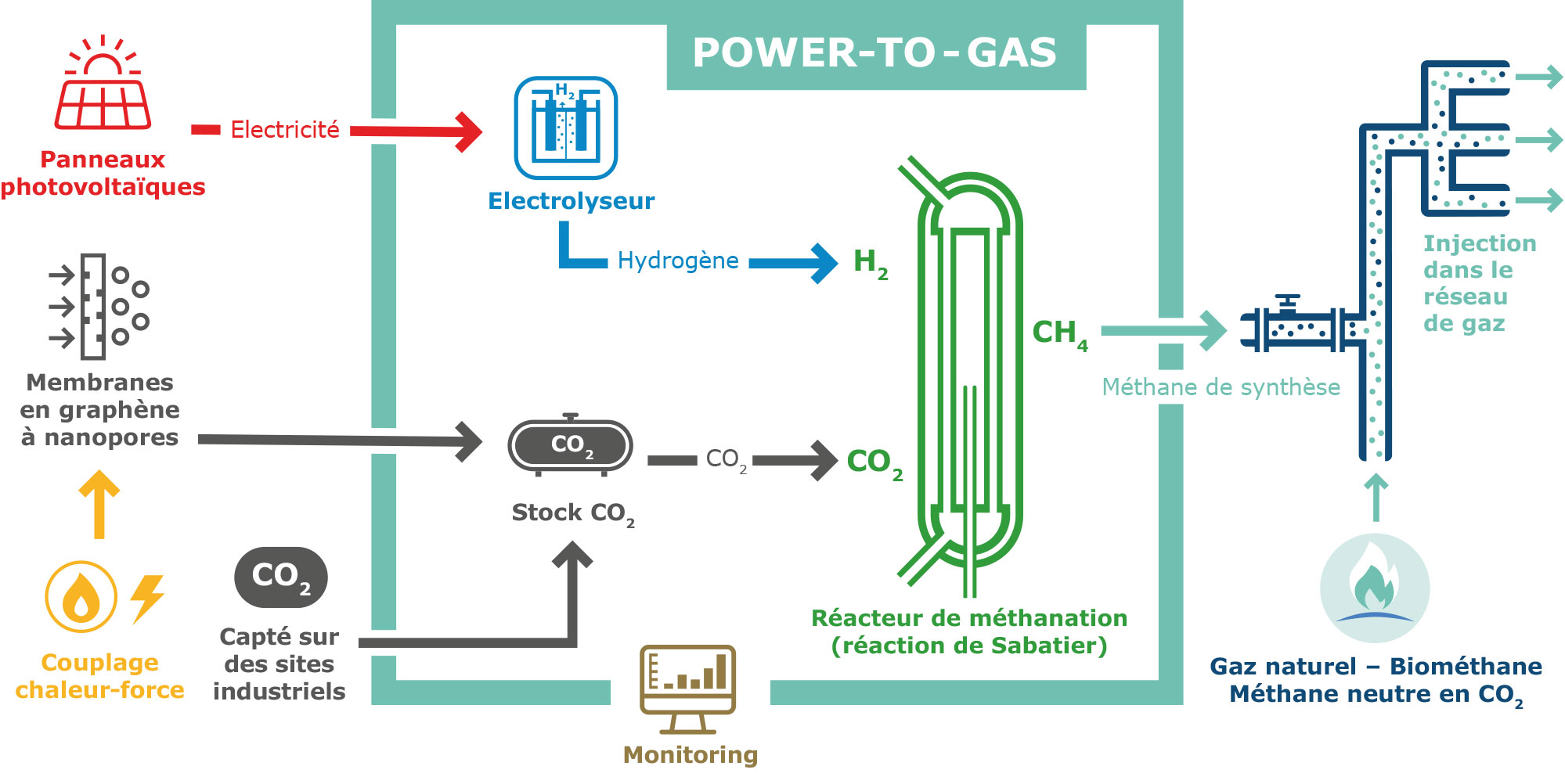

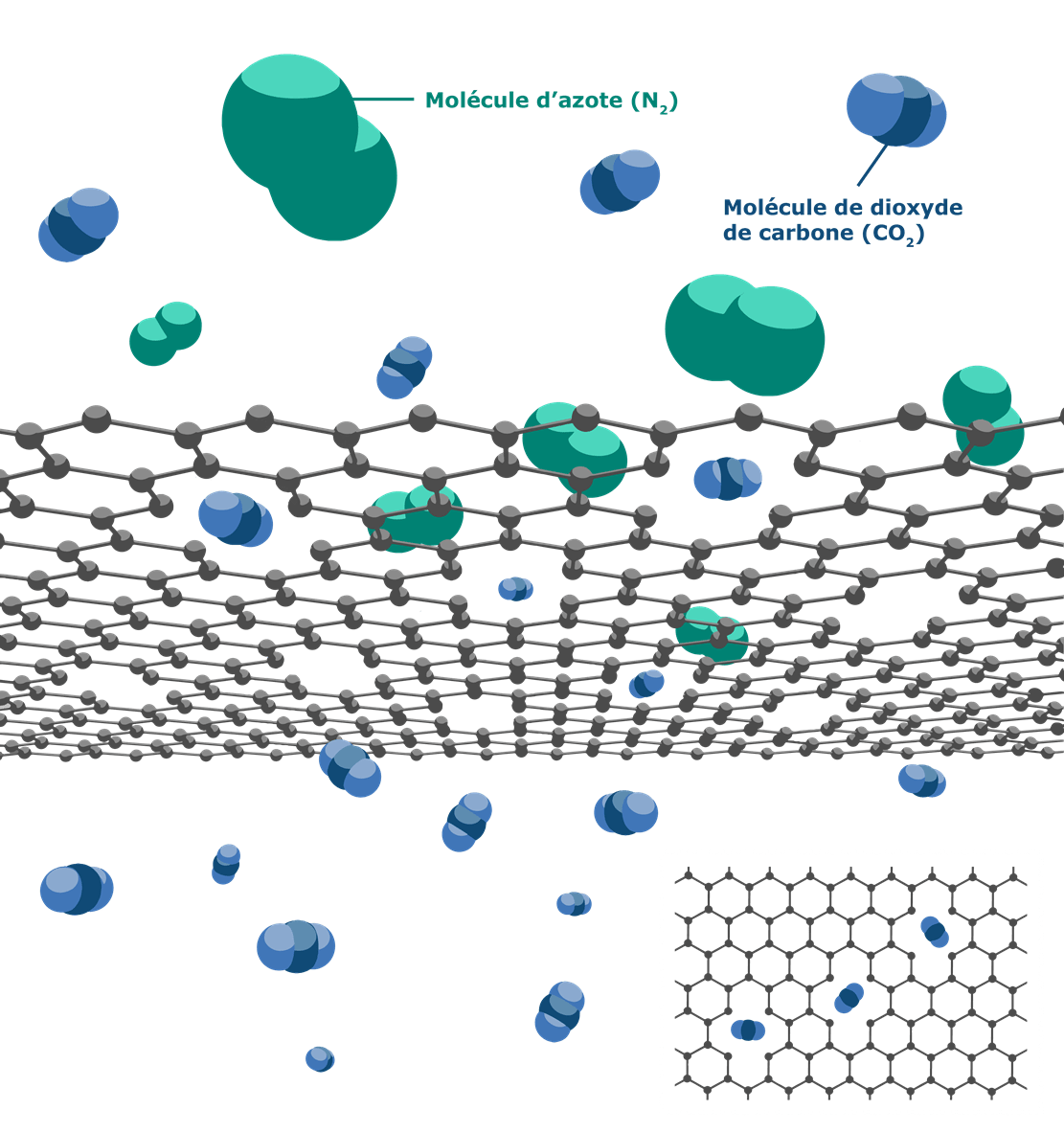

At the same time, Gaznat keeps on investing in research to sustainably decarbonize its activities through a competence center on the capture, storage and use of CO2 for the production of syngas, in partnership with the Ecole Polytechnique Fédérale de Lausanne (EPFL). This strategic cooperation with EPFL has resulted in two innovations ready for industrial testing: the methanation reactor and nanopore graphene membranes.

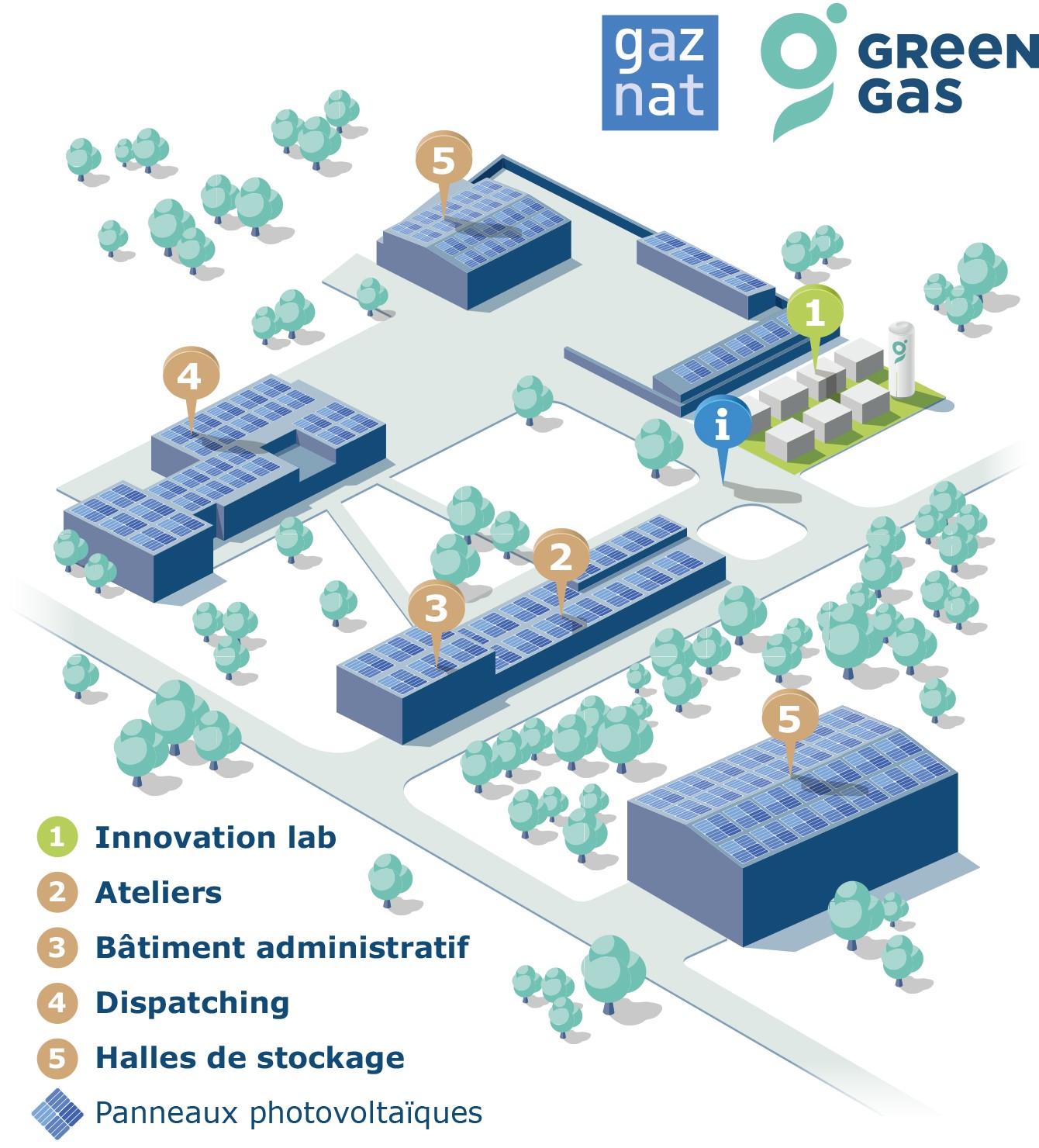

The integration of the R&D program into the reshaping of the dispatching center has given rise to the GreenGas project: a unique energy project in French-speaking Switzerland, featuring the largest industrial-scale laboratory in this area for the development of CO2-neutral renewable gases, the Innovation Lab, inaugurated on August 30, 2023.

Interview with René Bautz, CEO

Map of the dispatching center at Aigle - 2023

Map of the dispatching center at Aigle - 2023 Schematic diagram of the GreenGas concept with its central Power-to-Gas plant

Schematic diagram of the GreenGas concept with its central Power-to-Gas plant Graphene network separating carbon dioxide from nitrogen

Graphene network separating carbon dioxide from nitrogen The Innovation Lab

The Innovation Lab